VIRIDIS Cooling Tower Gearboxes

Overview

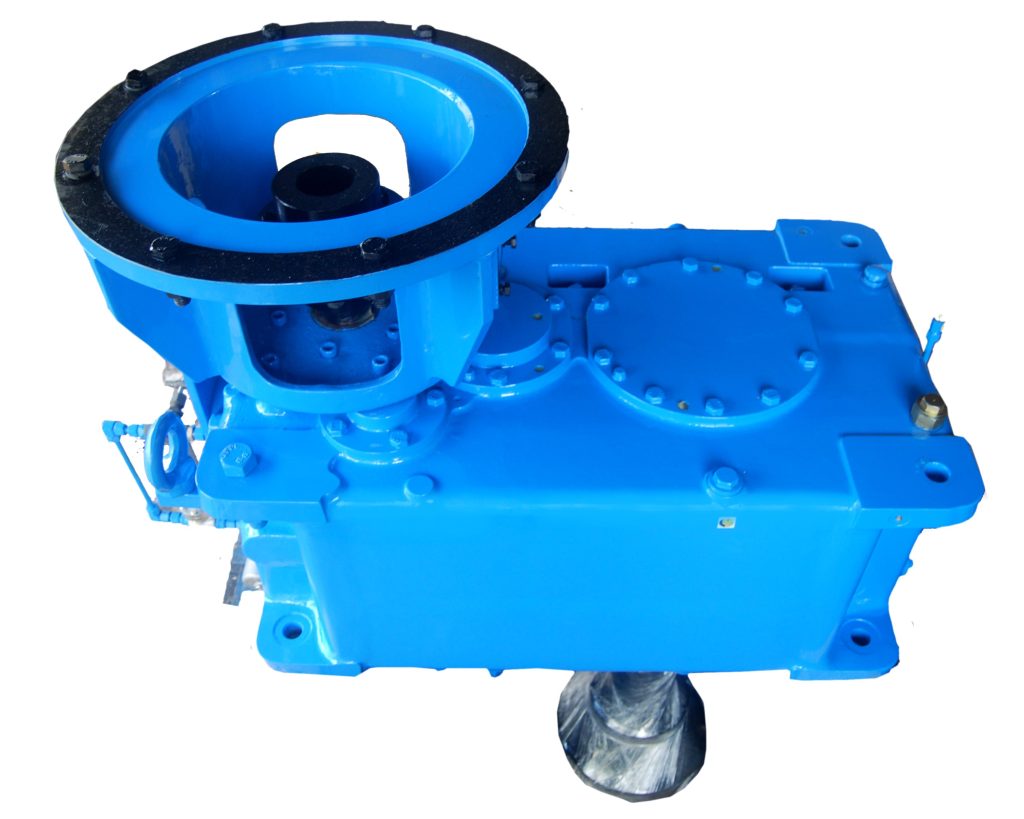

Cooling tower gearboxes are essential components of cooling towers. The role of the gearbox is to transmit power from the motor to the fan blades, which circulate the air and cool the water in the tower.

The gearbox helps to increase the rotational speed of the motor and transmit the power to the fan blades. It also allows for the fan speed to be adjusted to meet the cooling requirements of the tower. The gearbox is designed to operate under high torque loads, high temperature, and high humidity conditions, which are typical in cooling tower environments.

VIRIDIS cooling tower gearboxes are purposefully designed and are engineered to offer excellent durability, maximum energy savings, and compatibility with various cooling tower systems.

Our gearboxes are engineered to handle high torque loads, to operate reliably in high humidity environments that are ideal for achieving optimal cooling tower performance and ensuring long-lasting service life. Regular maintenance and inspection of our gearboxes can ensure consistent, efficient, and dependable cooling tower operation

Types of cooling tower gearboxes

VIRIDIS

Single Reduction Gearbox

Advantages:

Cost-effective: Single reduction gearboxes are generally less expensive than other types of gearboxes, making them a cost-effective option for smaller cooling tower applications.

Simple Design: Single reduction gearboxes have a simple design with fewer gears, making them easy to maintain and repair. This also means that they have fewer parts that could potentially fail, reducing the risk of downtime.

Higher Efficiency: Single reduction gearboxes have higher efficiency compared to double or triple reduction gearboxes. This is because they have fewer gear sets, resulting in less power loss due to friction.

Smaller Footprint: Single reduction gearboxes have a smaller footprint, which makes them ideal for cooling towers with limited space.

Quiet Operation: Single reduction gearboxes produce less noise compared to double or triple reduction gearboxes. This makes them a suitable option for applications where noise levels need to be kept to a minimum.

Better Compatibility: Single reduction gearboxes are compatible with a wide range of motors, making them a versatile option for cooling tower applications.

VIRIDIS

Double Reduction Gearbox

Advantages:

Improved efficiency: A double reduction gearbox can help to improve the overall efficiency of the cooling tower system by reducing the speed of the motor and increasing the torque output.

Increased reliability: With two sets of gears working together, a double reduction gearbox can provide increased reliability and durability over a single reduction gearbox.

Smaller footprint: Double reduction gearboxes are typically more compact than other types of gearboxes, which can help to reduce the overall footprint of the cooling tower system.

Enhanced performance: By reducing the speed of the motor, a double reduction gearbox can help to enhance the performance of the cooling tower system by providing greater control over the flow of water and air.

Reduced maintenance: With its rugged construction and reliable performance, a double reduction gearbox can help to reduce the need for maintenance and repairs over the long term.

Energy savings: By increasing the torque output and reducing the speed of the motor, a double reduction gearbox can help to reduce energy consumption and lower operating costs.

VIRIDIS

Triple Reduction Gearbox

Advantages:

High torque capacity: With three sets of gears working together, a triple reduction gearbox can provide a high torque capacity, which is ideal for heavy-duty cooling tower applications.

Improved efficiency: A triple reduction gearbox can help to improve the overall efficiency of the cooling tower system by reducing the speed of the motor and increasing the torque output.

Increased reliability: With three sets of gears working together, a triple reduction gearbox can provide increased reliability and durability over a single or double reduction gearbox.

Smaller footprint: Although slightly larger than double reduction gearboxes, triple reduction gearboxes are still relatively compact and can help to reduce the overall footprint of the cooling tower system.

Enhanced performance: By reducing the speed of the motor and increasing the torque output, a triple reduction gearbox can help to enhance the performance of the cooling tower system by providing greater control over the flow of water and air.

Energy savings: By increasing the torque output and reducing the speed of the motor, a triple reduction gearbox can help to reduce energy consumption and lower operating costs.

VIRIDIS

Bevel Gearbox

Advantages:

High torque capacity: Bevel gears are designed to handle high torque loads, which makes them ideal for cooling tower applications where heavy loads are common.

Compact size: Bevel gearboxes are relatively small in size compared to other types of gearboxes, which makes them ideal for applications where space is limited.

High efficiency: Bevel gearboxes are designed for high efficiency, which helps to reduce energy consumption and operating costs.

Smooth operation: Bevel gears provide smooth and quiet operation, which can help to reduce noise pollution in the surrounding area.

High precision: Bevel gearboxes are designed for high precision, which helps to ensure accurate and reliable operation.

Versatile mounting options: Bevel gearboxes can be mounted in a variety of different orientations, which makes them versatile and adaptable to different cooling tower designs.

Low maintenance: Bevel gearboxes require minimal maintenance, which helps to reduce downtime and repair costs over the long term.

Durability: Bevel gearboxes are known for their durability and long service life, which makes them a reliable choice for cooling tower applications.

VIRIDIS

Worm Gearbox

Advantages:

High torque capacity: Worm gearboxes are designed to handle high torque loads, which makes them ideal for cooling tower applications where heavy loads are common.

Self-locking capability: Worm gears have a self-locking capability, which means they can prevent the reverse rotation of the output shaft, providing additional safety and stability for the cooling tower.

High efficiency: Worm gearboxes have high efficiency, which helps to reduce energy consumption and operating costs.

Smooth operation: Worm gearboxes provide smooth and quiet operation, which can help to reduce noise pollution in the surrounding area.

Compact size: Worm gearboxes are compact in size, which makes them ideal for applications where space is limited.

Versatile mounting options: Worm gearboxes can be mounted in a variety of different orientations, which makes them versatile and adaptable to different cooling tower designs.

Low maintenance: Worm gearboxes require minimal maintenance, which helps to reduce downtime and repair costs over the long term.

Durability: Worm gearboxes are known for their durability and long service life, which makes them a reliable choice for cooling tower applications.

High reduction ratio: Worm gearboxes have a high reduction ratio, which means they can provide significant torque amplification, making them ideal for cooling tower applications that require high torque output.

VIRIDIS

Helical Gearbox

Advantages:

High efficiency: Helical gearboxes are known for their high efficiency, which helps to reduce energy consumption and operating costs.

Smooth and quiet operation: Helical gears provide smooth and quiet operation, which can help to reduce noise pollution in the surrounding area.

High torque capacity: Helical gearboxes are designed to handle high torque loads, which makes them ideal for cooling tower applications where heavy loads are common.

Compact size: Helical gearboxes are relatively compact in size compared to other types of gearboxes, which makes them ideal for applications where space is limited.

Versatile mounting options: Helical gearboxes can be mounted in a variety of different orientations, which makes them versatile and adaptable to different cooling tower designs.

Low maintenance: Helical gearboxes require minimal maintenance, which helps to reduce downtime and repair costs over the long term.

Durability: Helical gearboxes are known for their durability and long service life, which makes them a reliable choice for cooling tower applications.

High reduction ratio: Helical gearboxes have a high reduction ratio, which means they can provide significant torque amplification, making them ideal for cooling tower applications that require high torque output.

Ability to handle high-speed applications: Helical gearboxes can handle high-speed applications, which makes them ideal for cooling tower applications where high speed is required.

VIRIDIS

Planetary Gearbox

Advantages:

High torque capacity: Planetary gearboxes are designed to handle high torque loads, which makes them ideal for cooling tower applications where heavy loads are common.

Compact size: Planetary gearboxes are relatively small in size compared to other types of gearboxes, which makes them ideal for applications where space is limited.

Smooth and quiet operation: Planetary gears provide smooth and quiet operation, which can help to reduce noise pollution in the surrounding area.

Versatile mounting options: Planetary gearboxes can be mounted in a variety of different orientations, which makes them versatile and adaptable to different cooling tower designs.

Low maintenance: Planetary gearboxes require minimal maintenance, which helps to reduce downtime and repair costs over the long term.

Multiple gear ratios: Planetary gearboxes offer multiple gear ratios, which allows them to provide a wide range of torque and speed outputs, making them versatile and adaptable to different cooling tower requirements.