Structured Packing

VIRIDIS is a specialized engineering, design, construction and installation contractor with years of experience in structured packing technology.

We provide customized solutions for distillation, absorption, and other mass transfer processes using various types of structured packing. Our team of experts has the expertise to design, construct, and install structured packing systems for a wide range of applications, from small-scale laboratory experiments to large-scale industrial operations. We are committed to delivering high-quality services and ensuring our clients achieve their desired results, on-time and within budget.

At VIRIDIS, we pride ourselves on providing exceptional customer service, technical expertise, and innovative solutions to meet your needs.

Choice of Materials

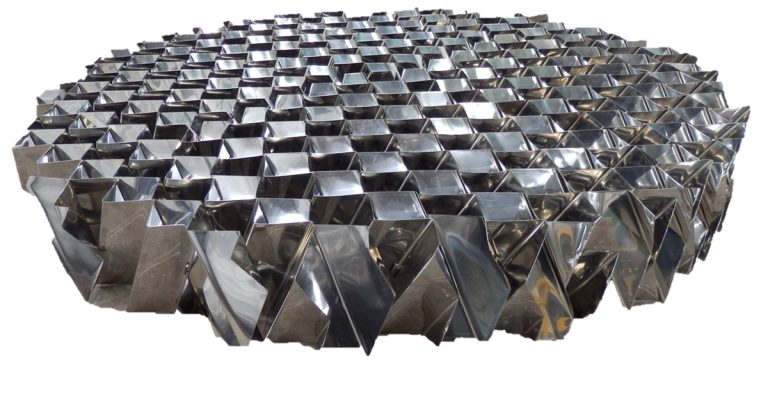

Metal Sheets

VIRIDIS manufacture structured packing made from metal sheets that provides high strength and durability. The sheets are corrugated to increase the surface area and promote mass transfer.

Examples:

Stainless Steel

Nickel

Monel

Copper

Titanium

Plastic

VIRIDIS manufacture structured packing made from plastic materials that offers resistance to corrosion and chemical attack. Plastic structured packing is lightweight and can be easily installed in distillation columns.

Examples:

Polypropylene (PP)

Polyvinyl chloride (PVC)

Polytetrafluoroethylene (PTFE)

Polymethylpentene (PMP)

Fluorinated ethylene propylene (FEP)

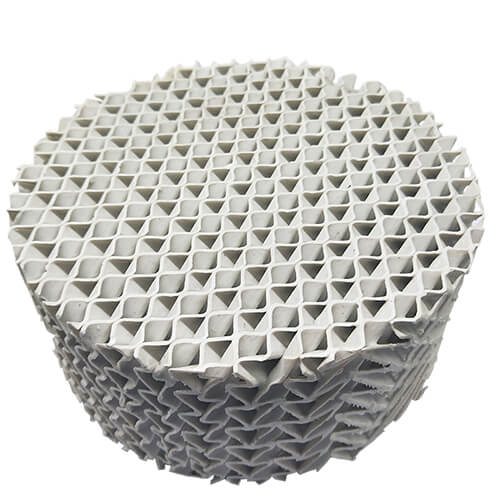

Ceramic

VIRIDIS manufacture structured packing made from ceramic materials that provides high thermal stability and resistance to abrasion. Ceramic structured packing can withstand high temperatures and harsh chemical environments.

Examples:

Alumina

Zirconia

Silicon carbide

Mullite

Cordierite

Carbon

VIRIDIS manufacture structured packing made from carbon materials that offers high thermal conductivity and resistance to corrosion. Carbon structured packing is suitable for distillation applications involving corrosive or high-temperature fluids..

Examples:

Graphite

Carbon Fiber

Activated Carbon

Carbon Nanotubes

Composites

VIRIDIS manufacture structured packing made from composite materials that combines the strengths of different materials to provide high performance and durability.

Examples:

Metal-plastic composites

Metal-ceramic composites

Ceramic-plastic composites

Carbon-metal composites

Structured Packing Types

Wire Gauze Packing

Wire gauze packing is a type of structured packing that consists of woven wire mesh in the form of a grid that is rolled into a cylindrical shape. This type of packing provides high surface area for mass transfer and is widely used in distillation columns for separation of various components.

Benefits of Wire Gauze Packing:

- High mechanical strength makes it suitable for high-pressure and high-temperature applications.

- Provides high efficiency and low pressure drop for optimal performance in distillation processes.

- Corrosion-resistant, making it ideal for use in corrosive environments.

- Low fouling tendency, reducing maintenance requirements and downtime.

Applications of Wire Gauze Packing:

- Separation of hydrocarbons in the oil and gas industry.

- Separation of ethanol and water in the chemical industry.

- Separation of pharmaceutical compounds in the pharmaceutical industry.

- Separation of organic acids in the food and beverage industry.

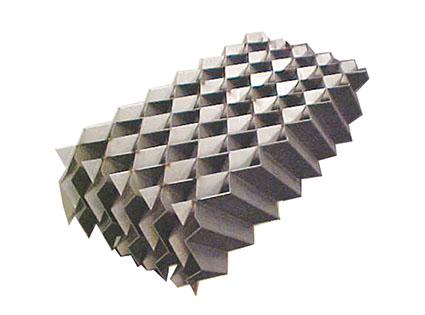

Grid Packing

Grid packing is a type of structured packing that provides a high surface area for mass transfer in distillation columns. It consists of a complex grid structure of woven wire mesh that offers higher efficiency and improved performance compared to other types of packing.

Benefits of Grid Packing:

- Offers higher surface area for mass transfer, allowing for improved efficiency and performance.

- Provides low pressure drop, reducing energy consumption and costs.

- Corrosion-resistant, making it ideal for use in corrosive environments.

- Suitable for high-temperature and high-pressure applications, offering reliable and durable performance.

Applications of Grid Packing:

- Separation of hydrocarbons in the oil and gas industry.

- Separation of organic acids in the food and beverage industry.

- Separation of chemicals in the chemical and petrochemical industries.

- Separation of pharmaceutical compounds in the pharmaceutical industry.

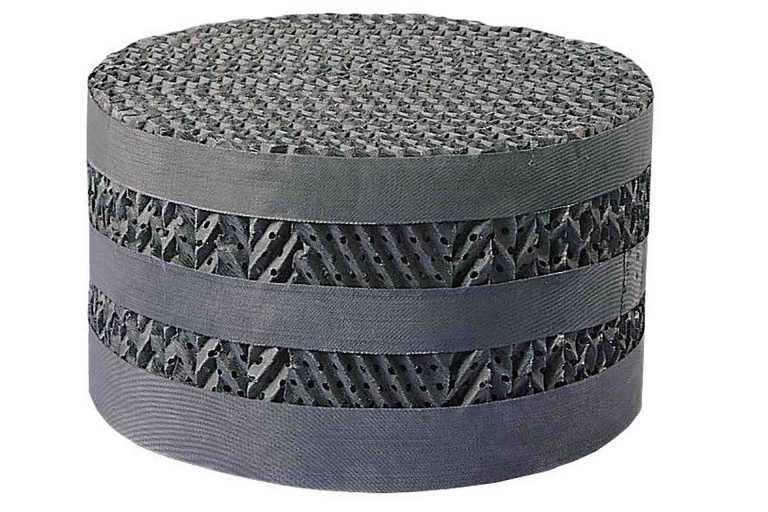

Perforated Plate Packing

Perforated plate packing is a type of structured packing that consists of a series of perforated plates stacked on top of each other in a column. The plates are typically made of metal and are designed with a pattern of perforations that allow for gas and liquid to flow through the packing.

Benefits of Perforated Plate Packing:

- Offers high mechanical strength, making it suitable for high-pressure and high-temperature applications.

- Provides high mass transfer efficiency and low pressure drop, allowing for efficient separation of components.

- Corrosion-resistant, making it ideal for use in corrosive environments.

- Easy to clean and maintain, reducing downtime and maintenance costs.

Applications of Perforated Plate Packing:

- Separation of hydrocarbons in the oil and gas industry.

- Separation of chemicals in the chemical and petrochemical industries.

- Separation of organic acids in the food and beverage industry.

- Separation of pharmaceutical compounds in the pharmaceutical industry.

Structured Packing with Channels

Structured packing with channels is a type of structured packing that consists of a series of vertical channels with inclined corrugated walls. These channels provide a high surface area for mass transfer and allow for efficient separation of components in distillation columns.

Benefits of Structured Packing with Channels:

- Offers high mass transfer efficiency and low pressure drop, allowing for efficient separation of components.

- Provides uniform liquid distribution and increased vapor-liquid contact, leading to better separation performance.

- Corrosion-resistant, making it ideal for use in corrosive environments.

- Easy to install and maintain, reducing downtime and maintenance costs.

- Can be designed with a variety of channel sizes and shapes to meet specific separation requirements.

Applications of Structured Packing with Channels:

- Separation of hydrocarbons in the oil and gas industry.

- Separation of chemicals in the chemical and petrochemical industries.

- Separation of organic acids in the food and beverage industry.

- Separation of pharmaceutical compounds in the pharmaceutical industry.